Background

Cotton swabs, also known as cotton buds or Q-tips, were invented by Leo Gerstenzang in the 1920s. He observed his wife wrapping cotton around toothpicks to clean their baby's ears and was inspired to create a safer and more efficient tool for the same purpose. He founded the Leo Gerstenzang Infant Novelty Co. in 1923 and started producing cotton swabs. Over time, these small sticks with cotton tips gained popularity for various uses beyond cleaning ears, such as applying makeup, precision cleaning, and crafts. However, it's important to note that medical professionals advise against inserting cotton swabs into the ear canal, as it can push wax deeper or cause injury.

Design and Development Advantage

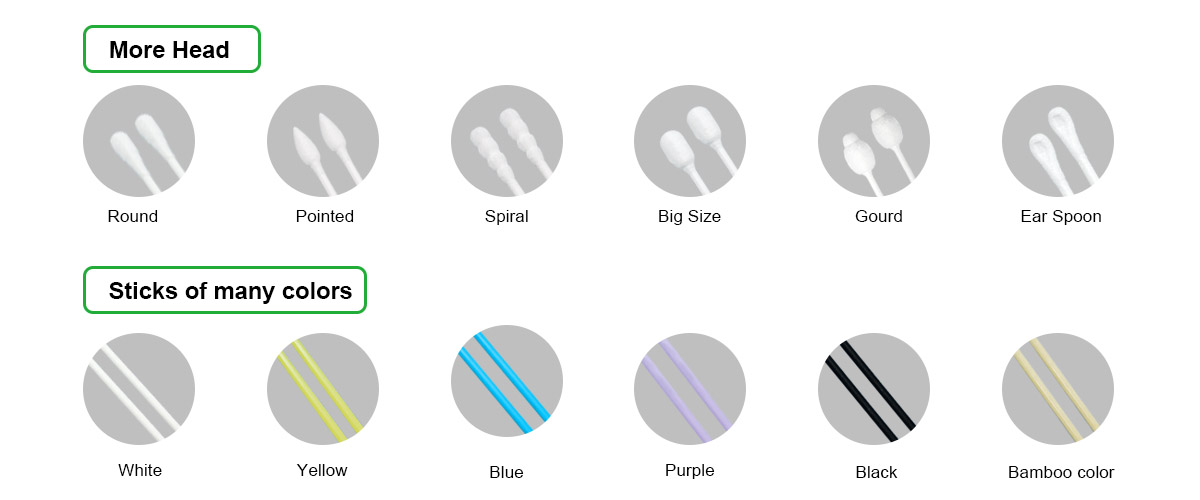

A cotton swab typically consists of a small wooden or plastic stick with one or both ends covered in tightly wound cotton fibers. The cotton ends are designed for various purposes, such as cleaning or applying substances to small areas, while the stick provides a handle for easy manipulation.

Cotton swab design has advanced significantly since the 1920s. For most applications, wooden sticks ,which are replaced by paper stick, and were less likely to splinter and puncture delicate ear tissue. The thin paper rods were made by rolling a heavy gauge paper. More recently, plastic has become a popular choice for spindle material because it offers improved flexibility and imperviousness to water. However, care must be taken to design the plastic shaft so that it does not poke through the cotton mass at the end of the stick. To prevent this from occurring, swabs have been designed with a number of special features. For example, some swabs are made with a protective plastic cap on the end of the spindle, under the cotton coating. Others use a cushioning element, like a dab of soft hot melt adhesive, to protect the end of the stick should it protrude through the body of the tip during manipulation. A third way of circumventing this problem involves a process, which results in a swab with a flared tip. This flared tip can not penetrate too deeply into the ear because of its larger diameter.

Though they should not be inserted into the ear canal due to the risk of pushing wax deeper inside.

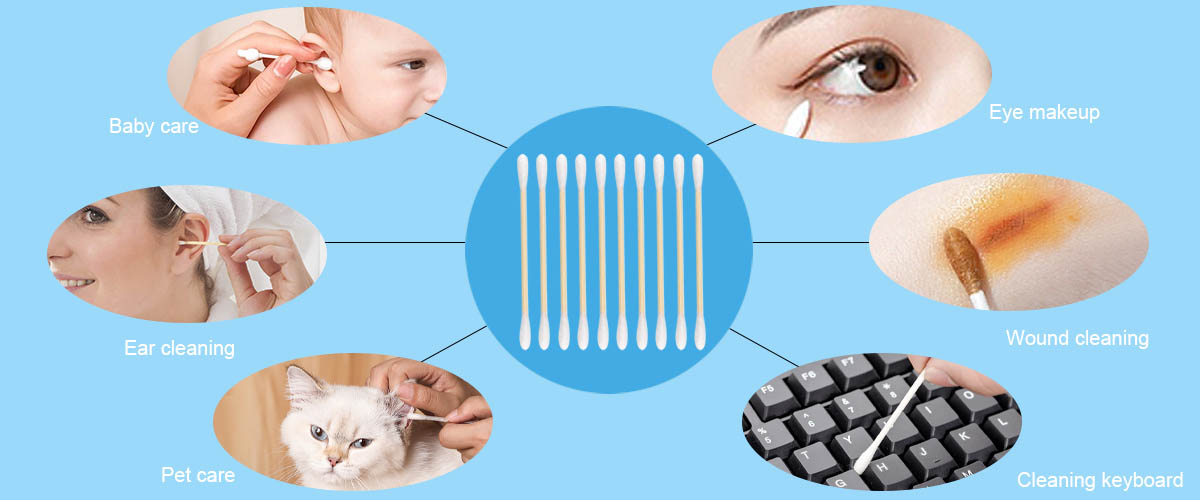

Makeup Application/Removal: They are commonly used in applying or removing makeup, especially for precise touch-ups around the eyes and lips.

Crafts and Hobbies: Cotton swabs can be used in various craft projects, such as painting, detailing, and applying small amounts of glue or other materials.

First Aid: They can be used for applying ointments, creams, or disinfectants to small wounds or minor burns.

Household Cleaning: Cotton swabs are handy for cleaning small and hard-to-reach areas, such as the corners of electronics, keyboards, or delicate objects.

Remember, while cotton swabs are versatile tools, it's important to use them safely and according to their intended purpose to avoid injury or other risks.

structure

Although the cotton swab is small, it can serve people well in many scenarios in life, in medical treatment, and in work. For example, if we fall and need to wipe and apply medicine, a clean Q-tip avoids the bacteria we use to contact the wound, and the cotton on both ends can absorb the medicine and apply it better.

Development prospect

In the cotton era, cotton is closely related to human life, cotton swabs can be seen everywhere in various fields, we not only have the technology to transform the rod, but also can transform the diameter and shape of the cotton head, with the growth of global industrialization and the diversity of the market, making the cotton swabs more and more diversified, and have the function of the traditional single, In the future, the market demand for cotton swabs also has its rules to require the change of cotton swabs, so the advantages of cotton swabs still need to rely on the market.

Raw Materials

There are three primary components involved in swab manufacture: the spindle or stick, which forms the body of the swab; the absorbent material coated onto the spindle ends; and the package used to contain the swabs.

Spindle

Spindles can be sticks made of wood, rolled paper, or extruded plastic. They can be made to different specifications depending on the intended use. Personal care products are fairly small and lightweight and are only about 3 in (75 mm) long. Swabs made for industrial use may be more than twice as long and are typically made of wood for greater rigidity.

Absorbent end material

Cotton is most often used as an end covering for swabs because of its absorbent properties, fiber strength, and low cost. Blends of cotton with other fibrous materials may also be used; rayon is sometimes used in this regard.

Packaging

Packaging demands vary depending on the application for the swab. Some personal hygiene swabs, like Q-tips, are packaged in a clear plastic box (known as a blister pack) which is attached to a fiberboard backing. Chesebrough-Ponds holds a patent on the design of a self-dispensing package for Q-tip products. This patent describes a package made of a plastic bubble body with small projections molded into the plastic for the purpose of re-securing the cover onto the body. Other packaging used for swabs includes paper sleeves. This type of packaging is common for swabs used for microbiological applications, which must be kept sterile prior to use.

In addition, we have different packaging models, according to market research and export experience: European and American countries prefer paper sticks and cotton swabs packaged in square plastic boxes, compared with Japan and South Korea, more inclined to round boxes, because different countries have different aesthetic concepts, the design of the packaging appearance will be combined with local culture to design, but our bag packaging cotton swabs always occupy a dominant position in the market because of the cost advantage.

The Manufacturing Process

Different methods are used in swab manufacture depending on the design of the swab. In general the process can be described in three major steps: spindle fabrication, cotton application, and packaging of the finished swabs.

Quality Control

Many of quality control measures are used to ensure cotton swabs are acceptable. The spindles must be checked to ensure they are straight and free of imperfections, such as stress cracks or other molding defects. The cotton used to coat the ends must be of specific purity, softness, and fiber length. The finished swabs must be free from lose adhesive and sharp edges, and the tips must be tightly wrapped. These measures are especially critical for swabs designed for infant use. For swabs intended for other applications, other quality requirements may be more important. For example, swabs used for biological purposes must remain sterile until used. For some applications, lack of loose lint maybe imperative. The particular quality control requirements will vary with the application. Of course, each box of swabs must be weighed to make sure the correct number of swabs are packed in each box.

The Future

A more recent innovation used to help prevent the swab from damaging ear tissue is a swab with extra cotton filling the hollow spindle. To achieve the effect, the swab applicator is made by extruding a plastic tube over a resilient mass of cotton. One end of the stick is fitted with a cap and the other end has a more traditional swab-like protrusion of cotton. The cap can be removed and the fiber core filled with any liquid that is desired to be dispensed. This technique could be useful for applying a variety of cleaning fluids or topical medicines. Future developments in swab technology may play a role in space technology was well. The Micro Clean Company, under a technology license from National Aeronautics and Space Administration (NASA), has recently perfected the first cotton swab that has the absorption qualities of cotton yet meets NASA's lint-free, adhesive-free requirement for clean room use. This swab is enclosed in a nylon sheath and the wood handle is enclosed in a shrink film to prevent fiber release or other contamination. The shrink film allows the dowel to absorb more stress, making it easier to use and less likely to slip in the hand. The sheathing and shrink film can be custom designed for special applications or specific solvent compatibility.

Post time: Sep-04-2023